New Fourth Board Listed Enterprise Stock Code891135

tel:

New Fourth Board Listed Enterprise Stock Code891135

tel:

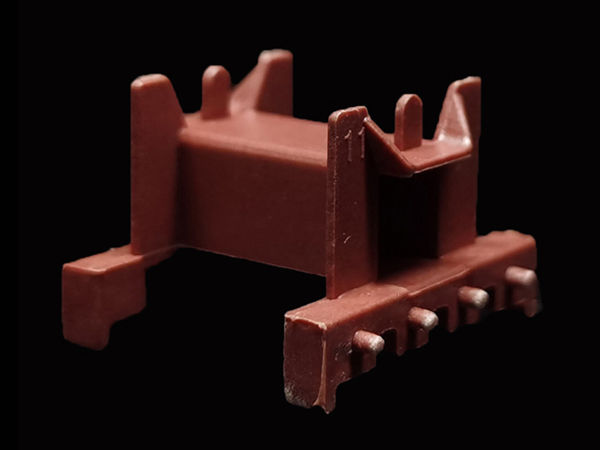

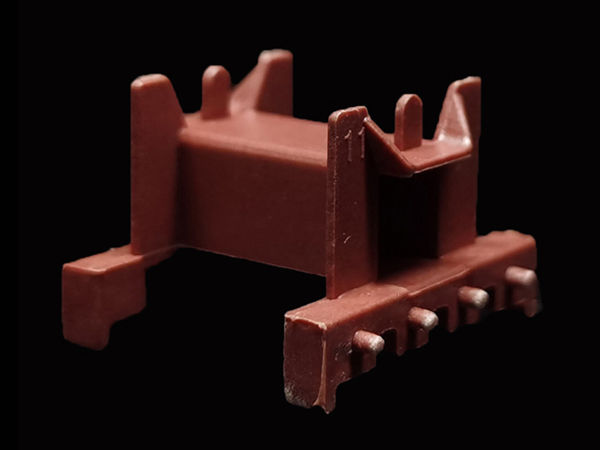

High-end nylon modified types are the repeating structural units of the molecular backbone, containing amide groups (—CONH—) A class of thermoplastic resins, including aliphatic polyamides, aliphatic-aromatic polyamides and aromatic polyamides. Aliphatic polyamide has many varieties, large output and wide application. It can be used as fiber and plastic. There are few varieties of aliphatic-aromatic polyamides, and the output is also small; aromatic polyamides are often referred to as polyaramids and are mainly used as fibers (aramid).

The modified types of aliphatic high-end nylon include nylon 6, nylon 66, and nylon 1010.

Actually, there is not much difference between nylon 6 and nylon 66. The reason why both are produced is just because DuPont invented nylon 6, and nylon 6 applied for a patent, so other companies invented nylon 6 in order to produce high-end modified nylon. The modified type of high-end nylon is the most common man-made fiber. When the stockings woven with nylon came out in 1940, they were very popular, and the high-end nylon modified varieties became famous in one fell swoop. Later, during World War II, nylon was used extensively to weave parachutes and ropes. But the original use of nylon was to make toothbrush bristles.

The modified type of high-end nylon belongs to polyamide, which has amino groups in its main chain. Amino groups are polar and will attract each other due to the action of hydrogen bonds. Therefore, nylon is easy to crystallize and can be made into high-strength fibers. Polyamide is a tough horny translucent or milky white crystalline resin, often made into cylindrical pellets. The molecular weight of polyamide used for plastics is generally 15,000 to 20,000.

The common characteristics of various polyamides are flame resistance, high tensile strength (up to 104MPa), wear resistance, good electrical insulation, heat resistance (the heat distortion temperature is above 150℃ under 455kPa), and the melting point is 150~250 ℃, the fluidity of molten resin is high, the relative density is 1.05-1.15 (adding filler can be increased to 1.6), mostly non-toxic.

Mobile Site